How To Remove Hardened Jb Weld

In my uses Im through working with it in about 15-20 minutes and I try to remove it within twenty minutes after that. JB Weld has tons of products available for specific types of repairs but the generic epoxies JB Weld and JB Weld KwikWeld are the main types.

Miller S Weld Mask Series Allows Welders To Weld In Spaces Where Access With Traditional Welding Helmets Is Limited Weld Welding Helmets Mask

This is the way Ive done it a few times.

How to remove hardened jb weld. The most controlled removal method would be to use a Dremel tool file sandpaper etc. If you are still worrying about your JB water weld not hardening properly then just knead the putty properly. Hopefully the clear is thick enough to allow a bit of work to finish.

Solvents dont work on it the only thing that works for JB Weld removal is some good old fashioned elbow grease. I have read here that you can cut the motor tube just above the retainer and then use a Dremmel and carefully grind out the left over tube and hardened JB Weld. How can I remove J-B Weld after it is fully cured.

Adhesive remover is only for use on surfaces of materials like wood or plastic. To grind off the JBW. This particular article is all about KwikWeld the fast-setting version of JB Weld epoxy.

I have a long piece of tubing that needs the weld removed. Unfortunately adhesive removers cant be used on the skin. When fully cured J-B Weld can only be removed by grinding or filing it off or by directly heating the product above the 600º maximum temperature threshold.

Buy Sell and Trade your Firearms and Gear. JB Weld for Radiators. JB Weld is hard and pretty strong but can be removed in some cases.

To grind off the JBW. Use a hard flat sanding block and fine open coat sandpaper. When fully cured J-B Weld can only be removed by grinding or filing it off or by directly heating the product above the 600 degree maximum temperature threshold.

Removing dried epoxy adhesive requires a lot more than your ordinary kitchen solutions. In terms of effectiveness the best way to get rid of cured epoxy is a specialized adhesive remover. I had to make a tool to do it so I decided to share the build process.

Never tried it but will when faced with the need. Use a hard strait edge to spread it. I clean my hands soon after I get the stuff on them.

I explain all the ways to r. I would try sanding lightly just on the JB Weld using finer as you get close to the paint. Put JB Weld on the exhaust header hole.

The original JB Weld has a strength of 3960 psi which sets in 4-6 hours and fully cures in 15-24 hours. I prefer MarineTex epoxy very hard stuff. I know this because I had to look it up last summer.

You have to knead until you see a uniform color. Firearm Discussion and Resources from AR-15 AK-47 Handguns and more. The most controlled removal method would be to use a Dremel tool file sandpaper etc.

Might I also suggest experimenting on a piece of scrap to get a feel for the process. If you need to remove JB Weld youre going to have to crack out the drill dremel sander or file just like you would with a metal. It is somewhat brittle so if you can remove the PR base you may be able to chip it off the pins of the bulb.

JB Weld is hard and pretty strong but can be removed in some cases. You can easily and quickly fix any water source and underwater items with it. Realized that it wouldnt hold up to the heat so had to remove it.

Have used it to completely reform ports on 2-cycle race engines after machining original casting completely away. JB water weld is your one-stop plumbing solution. How can I remove J-B Weld after it is fully cured.

Per JBs website info from last year grinding or filing or heat in excess of 600F is the only way to pull down hardened JB Weld. Slow process and you may have to buff the area when done. If you dont have hand cleaner or it doesnt work try acetone or lacquer thinner.

It is somewhat brittle so if you can remove the PR base you may be able to chip it off the pins of the bulb. When fully cured J-B Weld can only be removed by grinding or filing it off or by directly heating the product above the 600 degree maximum temperature threshold.

Laptop Hinge Snapped A While Back Mixed Some Jb Weld Plasticweld And Filled The Joint With It Held For A Couple Days But Some Of It Is Peeling Off Is This Bad

Can You Jb Weld Your Diff Youtube

J B Weld Waterweld Epoxy Putty Stick 2oz Walmart Com Walmart Com

J B Weld 8280 Original Professional Size Steel Reinforced Epoxy 10 Oz Amazon Sg Home Improvement

J B Weld 50112 Clearweld Quick Setting Epoxy Syringe Clear 25 Ml Buy Online At Best Price In Uae Amazon Ae

How To Remove Jb Weld The Complete Guide 2019

Pin By Kyle On Plumbing Bathtub Drain Bathtub Leaking Tub

How To Glue Metal With J B Weld Video 3 Of 3 Youtube

How To Remove Jb Weld The Complete Guide 2019

How To Remove Jb Weld Updated 2021

How To Remove Old Jb Weld Using Torch J B Weld Removal Youtube

J B Weld Offers Diy Winter Blast Repair Solutions

Ultimate Black Silicone 3oz J B Weld

Is Jb Weld Strong Enough To Repair A Broken Connecting Rod Let S Find Out Youtube

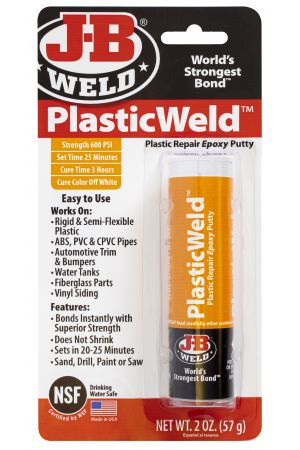

Plasticweld Epoxy Putty J B Weld

How To Remove Jb Weld The Complete Guide 2019

3 X 1 1 4 Thermo Rubber Toolbox Caster Set Of 4 Tool Box Rubber Casters Casters Wheels

Post a Comment for "How To Remove Hardened Jb Weld"